The Aerovent F20035601 Short Maximum Stop Stud is a small but essential part used in industrial ventilation systems. This component helps control the movement of different mechanical parts, making sure they don’t go beyond their safe limits. By preventing overextension, the stop stud protects the machinery and keeps everything running smoothly.

Understanding how the Aerovent F20035601 Short Maximum Stop Stud works is crucial for anyone in the industrial field. It not only enhances safety but also helps avoid costly repairs. This article will explore the features, applications, and benefits of this important component, showing why it’s vital for efficient operations.

What Makes the Aerovent F20035601 Short Maximum Stop Stud Essential?

The Aerovent F20035601 Short Maximum Stop Stud is an important part of many machines used in factories and other industrial places. It helps keep different parts of machines from moving too far. This control is very important because it prevents accidents and protects the machines from breaking down.

Understanding its role is key for people working in these environments. Without this small component, machines could experience damage or even cause injuries. That’s why the Aerovent stop stud is essential for smooth and safe operations in industrial systems.

How Does the Aerovent F20035601 Short Maximum Stop Stud Work?

The stop stud works by limiting the movement of mechanical parts. When machines operate, they have parts that move back and forth or up and down. The Aerovent F20035601 Short Maximum Stop Stud prevents these parts from going beyond their safe movement range.

- Limits Motion: It stops the parts at a safe point.

- Prevents Damage: This action keeps machines from breaking or wearing out too quickly.

- Ensures Safety: It helps protect workers from getting hurt by unexpected movements of machine parts.

When everything works as it should, productivity increases, and there are fewer problems during operations.

Key Features of the Aerovent F20035601 Short Maximum Stop Stud

Several features make the Aerovent F20035601 Short Maximum Stop Stud stand out in the industrial world. Knowing these features can help users understand its value better.

- Durable Material: The stud is made from strong materials that last a long time.

- Compact Size: Its small design allows it to fit easily into different machines.

- Easy to Install: Setting it up is simple, which means less downtime for machines.

These features contribute to its efficiency and reliability, making it a popular choice in various industrial applications.

Where is the Aerovent F20035601 Short Maximum Stop Stud Used?

This stop stud can be found in many different places and types of machines. It is commonly used in systems where movement needs to be controlled precisely. Here are some examples:

- HVAC Systems: In heating and cooling systems, it helps manage airflow.

- Industrial Fans: It keeps fan blades from moving too much, which can cause issues.

- Air Handling Units: This stud ensures the components move correctly for better air quality.

Using the Aerovent F20035601 Short Maximum Stop Stud in these applications promotes safety and efficiency.

The Benefits of Using the Aerovent F20035601 Short Maximum Stop Stud in Your Operations

Incorporating this stop stud into machines provides many benefits for industries. Businesses can see improvements in various areas by using this simple yet effective component.

- Increased Safety: The stud helps create a safer working environment by preventing accidents.

- Longer Equipment Life: It reduces wear on machines, meaning they last longer.

- Lower Repair Costs: Fewer breakdowns lead to lower maintenance expenses.

Overall, the Aerovent F20035601 Short Maximum Stop Stud can significantly improve the reliability of industrial operations.

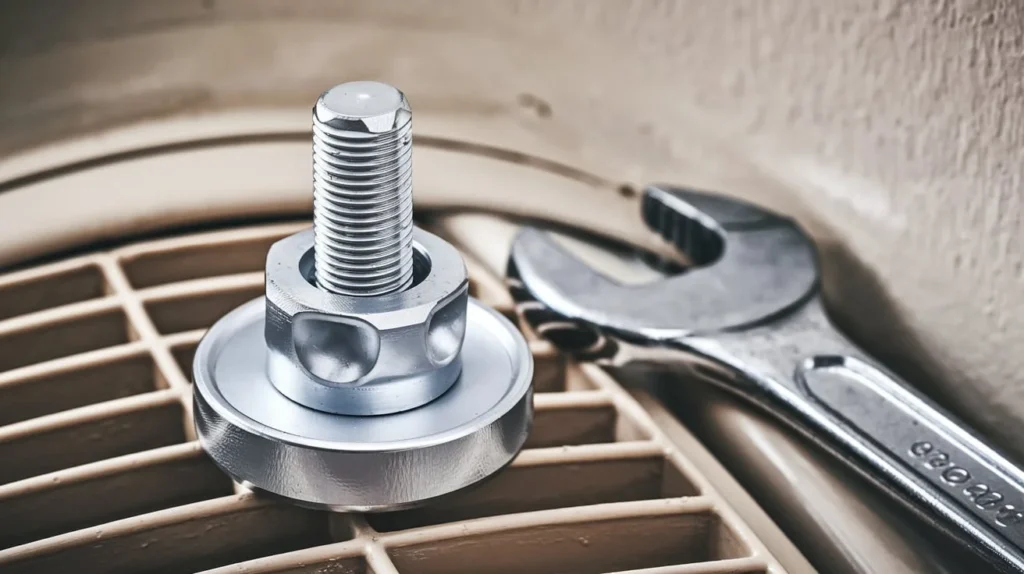

Step-by-Step Guide: Installing the Aerovent F20035601 Short Maximum Stop Stud

Installing the Aerovent F20035601 Short Maximum Stop Stud is a straightforward process. Following the right steps ensures that the stud works effectively. Here is a simple guide to help with the installation:

- Gather Tools: You will need basic tools like a wrench and screwdriver.

- Find the Right Spot: Identify where the stud will be placed in the machine.

- Secure the Stud: Use the tools to tighten the stud into place properly.

- Check Functionality: After installation, make sure everything moves correctly without overextending.

By following these steps, anyone can install the stop stud and ensure the machine operates safely.

Maintaining the Aerovent F20035601 Short Maximum Stop Stud for Longevity

Regular maintenance is essential for keeping the Aerovent F20035601 Short Maximum Stop Stud working well. Performing checks can prevent problems and extend the life of the component. Here are some maintenance tips:

- Inspect Regularly: Look for signs of wear or damage on the stop stud.

- Clean the Area: Dust and dirt can affect the stud’s performance, so keep the area clean.

- Replace When Needed: If the stud shows signs of damage, replace it quickly to avoid issues.

Taking care of the stop stud helps keep industrial systems running smoothly and safely.

Safety First: Why can Must-Have

Safety is a top priority in any industrial environment. The Aerovent F20035601 Short Maximum Stop Stud plays a crucial role in enhancing safety for everyone working around machines. Here’s why it is considered a must-have:

- Prevents Overextension: It stops parts from moving too far, reducing the chance of accidents.

- Reduces Risk of Injury: With controlled movement, operators and maintenance workers are safer.

- Ensures Compliance: Using this component helps meet safety regulations in the workplace.

Investing in the stop stud can lead to a safer working environment and fewer accidents.

Common Issues with it and How to Fix Them

While the Aerovent F20035601 Short Maximum Stop Stud is reliable, there can be some common issues. Knowing how to identify and fix these problems can save time and money.

- Wear and Tear: Over time, the stud may wear out. Regular inspections can catch this early.

- Loose Fitting: If it becomes loose, it can affect performance. Tighten it immediately if this happens.

- Dirt Build-Up: Dust can accumulate, affecting movement. Regular cleaning can prevent this issue.

By being proactive about these common problems, industries can maintain the effectiveness of their systems.

Future Trends: Innovations Involving the Aerovent F20035601 Short Maximum Stop Stud

Looking ahead, there are exciting trends in the world of industrial components like the Aerovent F20035601 Short Maximum Stop Stud. Innovations are happening to improve efficiency and safety even further.

- Smart Technology: Newer models may incorporate smart sensors for better monitoring.

- Sustainable Materials: Future stop studs might be made from eco-friendly materials to promote sustainability.

- Enhanced Durability: Ongoing improvements can lead to even stronger and longer-lasting components.

These advancements can help industries become more efficient and safe in their operations.

Conclusion

The Aerovent F20035601 Short Maximum Stop Stud is a small but mighty part of many machines. It plays a big role in keeping everything safe and running smoothly. By preventing parts from moving too far, it helps avoid accidents and keeps the machines in good shape. This means workers can do their jobs better without worrying about getting hurt or having machines break down.

Using the stop stud not only improves safety but also saves money in the long run. When machines last longer and need fewer repairs, businesses can focus on getting their work done. Overall, the Aerovent F20035601 Short Maximum Stop Stud is an important piece that helps make work environments safer and more efficient. Remember, taking care of this little part can lead to big benefits for everyone!